“Concrete Automation Upgrade in just 2 days !!!”

Upgrade your concrete plant automation system in 2 days!!!

iConcrete is the new industrial Automation for Concrete production, Cement Products & Ready Mix Industries.

iConcrete is based on new iOlabs innovative processing techniques like LEMS (Less Electronics More Stability), ATS (Auto Tuning System) , SCS (Self Care System) and supports any new technology Ethernet Controllers which provide reliability, speed and accuracy to the system.

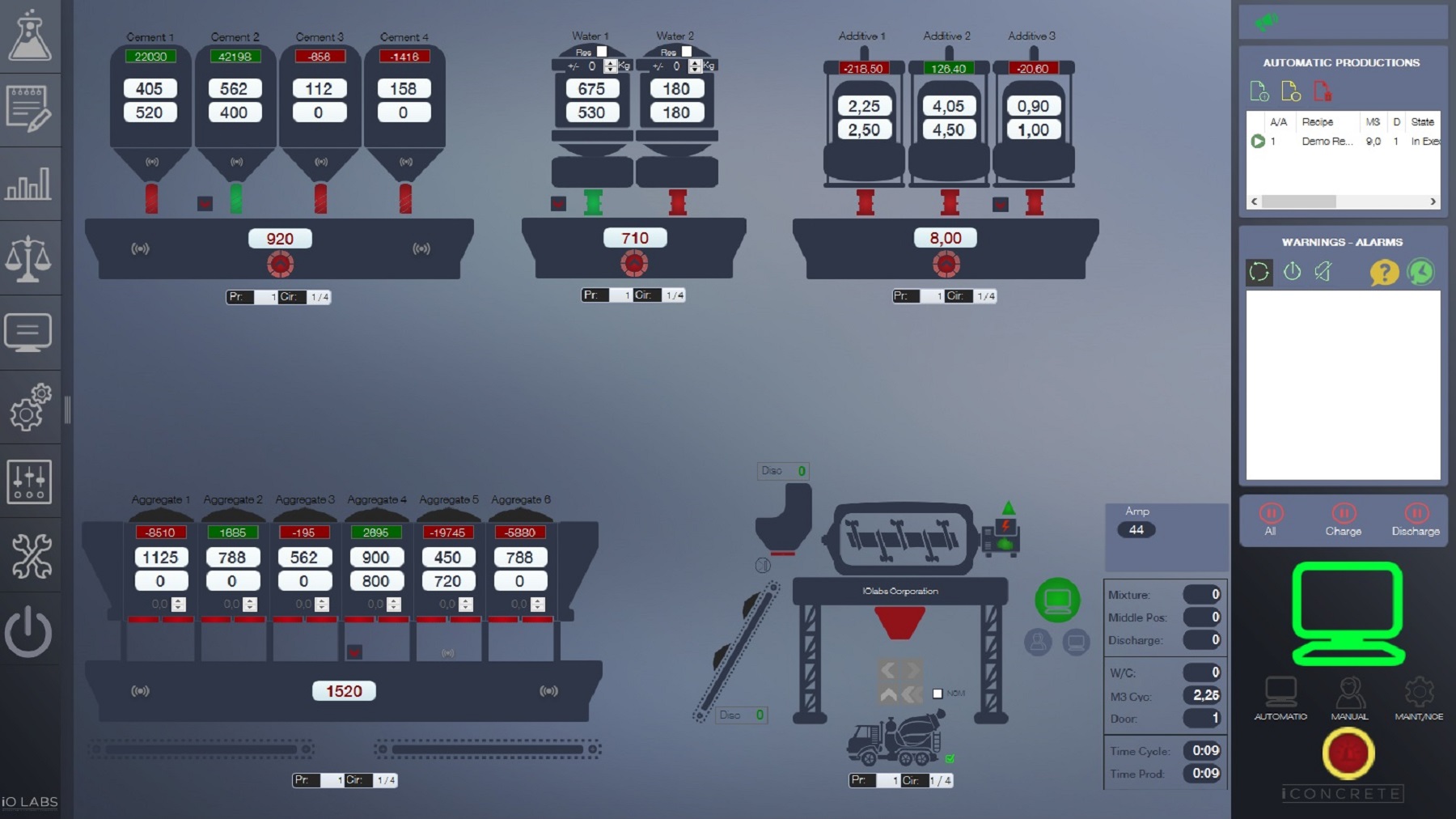

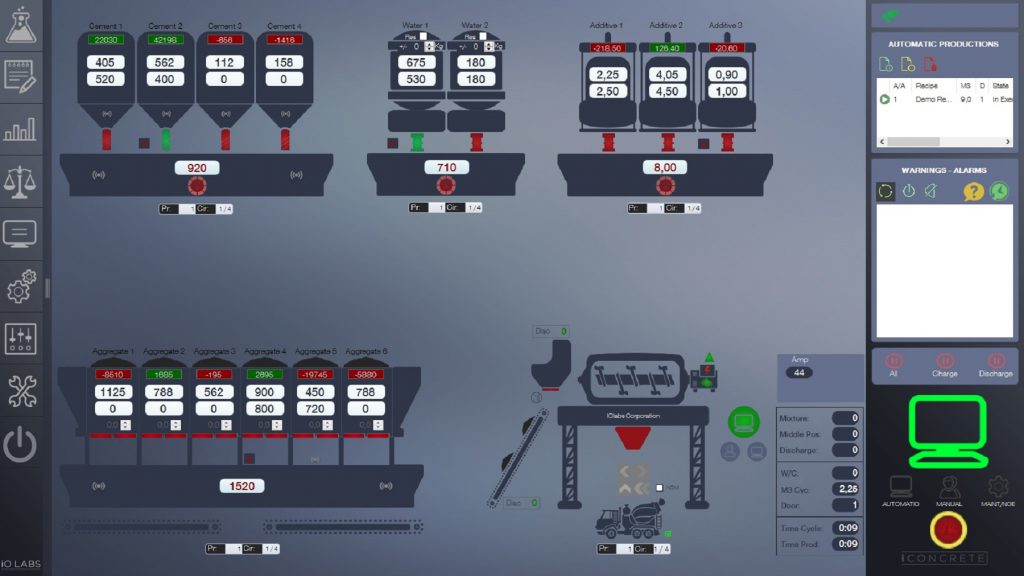

iConcrete comes with a new modern Animated design, an easy friendly environment which provides a more sophisticated and clear view to its operator about all machinery operations.

ADJUSTABLE ON ANY BATCHING PLANT

iOlabs has created the one fully adaptable Batching Plant, Concrete, Cement Products, Ready Mix Automation System, which is fully parameterized and supports any type of Machinery.

MODERN ANIMATED DESIGN

iConcrete uses elegant Animated Graphics and provides a complete view of the Machinery parts (Mixer, Scales, Storages Belts, AmperMeters, VoltMeters, etc) so operator can have the “Big Picture” and control of his industrial plant.

PRODUCTION SPEED & DATA ACCURACY

Using sophisticated automation techniques and innovative sampling & filtering methods, iConcrete manages to achieve maximum accuracy and speed during production.

INTERNATIONAL STANDARDS COMPLIANCE

iConcrete is compliant with all International & EU Concrete Compliance Standards.

AUTO TUNING SYSTEM

iConcrete is the only automation system which during operation checks and corrects system settings to optimize speed and accuracy depending on the behavior of the machine and materials.

SELF CARE SYSTEM

iConcrete automatically takes care to inform operator and proceed to any scheduled maintenance job defined by the operator.

ΡΥΘΜΙΣΕΙΣ & ΠΑΡΑΜΕΤΡΟΠΟΙΗΣΗ

Machinery parameters can easily be changed via iConcrete Settings Panel. Every operator is able to proceed to Analog Calibration of Scales without any technician assistance.

ΠΟΛΥΓΛΩΣΣΙΚΗ ΥΠΟΣΤΗΡΙΞΗ

iConcrete is already translated to many Languages and it is designed in order to be translated quickly to any Language.

Concrete Automation Electrical Panels

iOlabs Panels are Constructed by using the most modern and Reliable materials in order to provide to your machinery the Reliability it needs. Our new Modern Electrical Panels are smaller and have great performance.

Placed on metallic board that meets all European Security Specifications (ΙΡ 54) , they contain the main Power Switch and all the essential electrical parts for the Machinery Operation. It also Contains all the Motors connection Cabling and also all te Communication cabling with all the System Devices.

On the Panel also the main System Controller is Placed. Thi Controller is a new Generation Automation Controller that allows the system to communicate with the main Computer Wireless or not. These controllers are responsible for the communication between the main Computer and the Machinery Parts.