iOLABS, with its vast experience in the field of Concrete and Cement products automation, has created 2 new versions of iConcrete, iConcrete Ultimate Edition and iConcrete Enterprise Edition.

These two versions of Cement Product Automation make it possible for iConcrete to be installed on any Cement Product machine, no matter how complex it is.

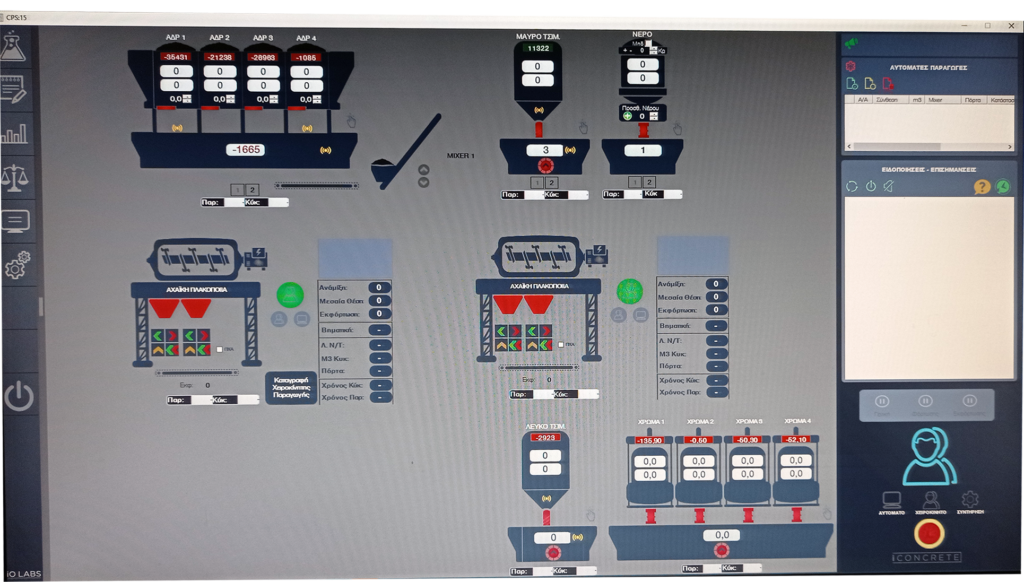

iConcrete Ultimate Edition and iConcrete Enterprise Edition support:

- 2 Mixers on the same machine with the ability to simultaneously manage producers for both mixers.

- 2 or more dumbbells (without restrictions on the number of silos) with their simultaneous use in 1 or 2 Mixer.

- 2 or more cement scales (without restrictions on the number of silos) with their simultaneous use in 1 or 2 Mixer.

- Water scales / Water meters with their simultaneous use in 1 or 2 Mixer.

- Chemical Mixer Scales with their simultaneous use in 1 or 2 Mixer.

- Color Balances with their simultaneous use in 1 or 2 Mixer.

- Microsilica scales with their simultaneous use in 1 or 2 Mixer.

- Aggregates transport wagons.

- Weighing Wagons.

- Removable type scales.

- Hygrometers / Hygrometers Mixer.

- Material Thermometers & Mixer.

Silo Moisture Meters / Mixer Hygrometers and Humidity Curves / Recipe.

iConcrete Ultimate Edition and iConcrete Enterprise Edition support both microwave moisture meters that calculate the amount of moisture in aggregates, as well as Mixer Hygrometers that measure how liquid the product is during Mixing.

In order to achieve excellent quality in the produced product, iConcrete Ultimate Edition and iConcrete Enterprise Edition support the operation through Moisture curves per Recipe, with which the operator “trains” the automation to add the appropriate amount of water during mixing to be produced. the end result.

Once this process is completed, the automation system can now independently produce the respective Recipe based on the hygrometer measurements and the humidity curve created for the given Recipe to be produced.

External Production Commands.

Both iConcrete versions (iConcrete Ultimate Edition / iConcrete Enterprise Edition) can operate autonomously using external production commands. Production commands are essentially a translation of an input signal into automation to a new production with a specific composition and quantity.

Production commands may derive from:

- Material level indicators on the hopper of a cement machine. As soon as the Automation receives input from the level indicator, a new production starts with the composition and the quantity predetermined by the operator.

- Buttons or button pads with independent production commands for each button.

- Tablet / Smartphone with built-in Application powered by iOLABS which allows the Tablet operator to customise elements of the composition if required, and to handle elements of automation after the mixer such as conveyor belts, material carriages etc.